High level thick copper power module circuit board, driving the future power core

- Release time: October 14, 2024

- Author: Founder

With the rapid rise of strategic emerging industries, the degree of industrial automation continues to improve. In the manufacturing industry, advanced production equipment and automated production lines are widely used, and the demand for high-power and high-precision power sources is increasing day by day. Various intelligent robots, CNC machine tools, automated warehousing systems, and other equipment require stable and reliable power supply to drive them, ensuring efficient and precise operation of the production process.

High-power DC power supplyAs the core cornerstone of electric drive, circuit boards have also ushered in new development opportunities and play a crucial role in modern advanced electronic devices and industrial systems.

What is a high-power DC power supply?

It is a power supply device capable of outputting high-power DC electrical energy. The output power typically ranges from several kilowatts to several hundred kilowatts or even higher. The output current and voltage are stable DC power, usually with adjustable output voltage and current range, which can not only meet the user's demand for high current and high voltage DC power supply, but also have great advantages in stabilizing voltage and current, making it very convenient to use. The application areas include industrial production, scientific research experiments, power transmission, new energy, communication, medical care, etc.

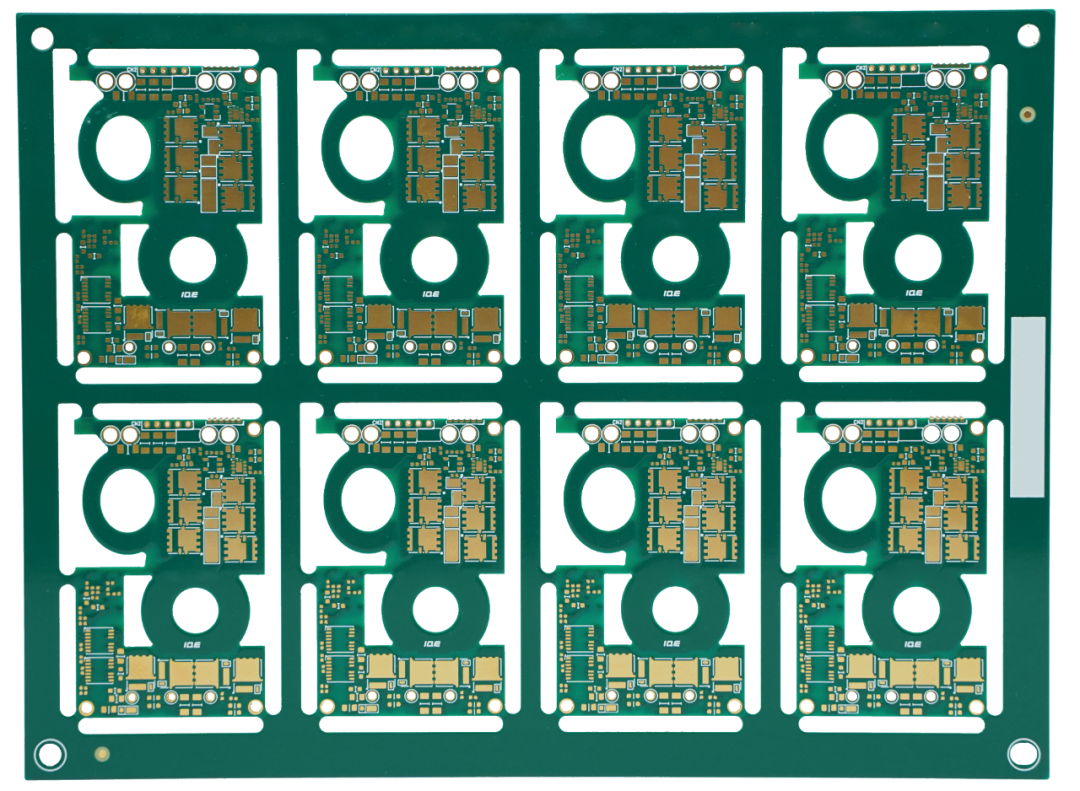

Recently, the company successfully delivered a high-level thick copper power module circuit board. Its advanced production technology and excellent performance have successfully achieved stable power supply management for high-power DC power supply, providing reliable power guarantee for high-power DC power supply equipment.

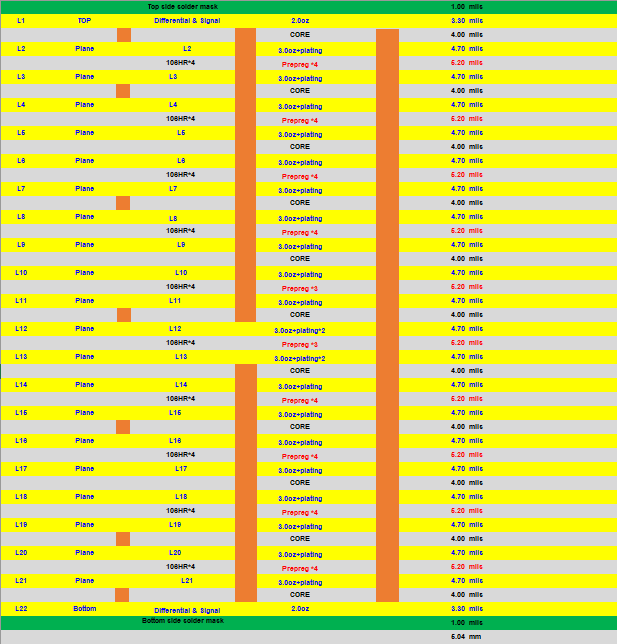

Product Layers | 22storey2Buried blind hole |

Product size | 36.8mm*58.4mm |

Surface Treatment | ENIG(Sinking Gold) |

Finished board thickness | 5.2±0.4mm |

application area | High power DC power module |

Using TaiyaoTu865 board,Thick copper foil designCapable of withstanding high voltage and high current loads from high-power DC power sources, providing low resistance current channels, reducing power loss and heat generation, and maintaining good stability and reliability.

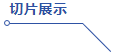

采用Two times of resin plug embedding blind holes, asymmetric compression design, minimum copper hole requirement of 50 μ m, aspect ratio of 15:1, high-density wiring design to meet the high-power output requirements of DC charging piles, achieving more stable and accurate signal transmission.

22 layer high thermal conductivity thick copper plate structure, inner layer copper thickness of 4oz, outer layer 2oz, minimum line width and spacing of 7.87mil/7.87mil. The thick copper layer has good heat dissipation characteristics, effectively improving power conversion efficiency, providing stable power supply for high-power devices, achieving precise power management, and meeting the needs of complex electronic systems.

The product is widely used in new energy fields such as solar energy, wind energy, and energy storage, such as DC charging piles. In the field of industrial automation, it can withstand high-power loads and harsh working environments, providing strong power support for industrial robots, CNC machine tools, automated production lines and other equipment, and reliable power guarantee for medical imaging equipment, life support systems, diagnostic instruments and other medical equipment.